Many shops today are still hesitant about changing their cutting tools. After all, traditional tools made of high-speed steel have proven to be extremely sharp and reliable for many machining tasks. Moreover, they tend to cost a lot less and can be easily sharpened or replaced if anything goes wrong. So carbide tools are seen as an unnecessary expense in many shops.

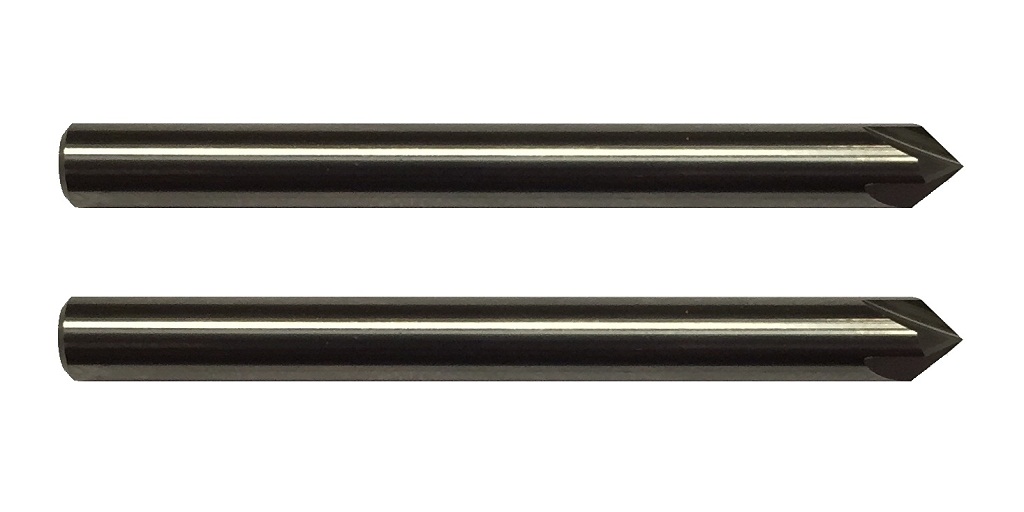

However, as the world of machining becomes more and more competitive, and average machining speeds increase, the shortcomings of metal tools are now more apparent than ever. This is evidently true for all types of tools, from spot drills to chamfer mills.

Steel´s flexibility is what gives it its cutting power as it can be molded and ground to extremely sharp edges without it losing structural integrity. However, this flexibility causes a lot of problems too. Their incredible sharpness is usually short-lived, and steel tools must be replaced often as they become dull quickly, especially when going through other metals or strong composites.

One other problem with steel tools is that they tend to wobble pretty hard when you are pushing the machine into fast RPMs. This wobbling makes it very difficult to produce accurate cuts and often causes the tool to walk off target. I have seen my fair share of scrapped parts because of misaligned holes.

Heat is another steel killer. HSS works pretty well under normal circumstances, however, it loses its hardness when it reaches temperatures close to 600°. In order to increase feed rates, you have to heavily depend on coolant fluids and lighter toolpaths, making high-speed steel actually kind of slow for many tasks. It is better to leave steel bits, end mills, and chamfer mills for low-volume applications.

Carbide cutting tools provide longer tool life, faster cut data, and increased rigidity. Carbide´s refractory properties allow machinists to increase speeds and feed rates without the risk of overheating the tool. Carbide chamfer mills can go through a lot of material without a problem, even when closing to the 1k degrees mark.

Carbide tools are not flexible at all. In fact, it is very brittle so it does not handle horizontal tensile forces too well. However, its rigidity gives carbide tools greater accuracy, giving your machine increased chances of staying true to the print.

While spot drills and chamfer mills made of carbide are not as sharp as high-speed steel tools, they do retain their cutting capabilities longer. This means that you don’t have to be constantly cycling through tools, which considerably reduces downtime. Their enhanced cutting data and resistance allows for longer, deeper cuts, drastically increasing part production times and accuracy in the long run, more than making up for their higher price tag.

However, you should only trust carbide tools from trusted manufacturers with a proven track record in the industry. Online Carbide is today one of the most trusted carbide tool suppliers. They produce high-quality carbide tools made in America and offer unbeatable manufacturer-direct prices for shops and hobbyists across the country.