When creating pipe threads, the quality of the threads determines how the parts can be used. Sometimes, we create threads that will only serve to hold two pieces together and provide stability. However, when we craft parts designed to transport liquids or gasses, these need to comply with extremely high industry standards to prevent leaks and efficiently transport resources.

National pipe taper was a national standard devised to help manufacturers create threaded pipes that are properly sealed and suited for transporting fluids and gasses. They were originally intended for steel and brass parts and pipes, but many manufacturers and shops today apply NPT threads on other materials such as cast iron, nylon, PVC, and more.

What makes these kinds of threads special is their flattened peaks and valleys or “Sellers” thread form. Their geometry provides extremely effective thread engagement, and they can be machined in both straight and tapered configurations. However, straight or parallel fittings do not provide adequate sealing unless a form of thread seal tape or plumber’s putty is used. Contrastingly, the tapered versions provide an extremely tight seal when torqued. There are even tighter designs, such as the National Pipe Taper Fuel, which have more demanding applications, especially for fuel connections in the automotive and aerospace industries.

As you can imagine, machining pipe threads that comply with these standards requires increased control over the manufacturing process that only carbide thread mill NPT configurations can provide.

But, Why Carbide Thread Mill NPT?

Traditionally, cutting threads is a task performed with tap and die systems. However, CNC machining has made it possible for workshops to adopt processes that can provide increased accuracy, reliability, and, more importantly, speed.

Tap and die processes require two sets of tools: dice for external threads (although, you can use a die for creating internal threads depending on the diameter and depth), and taps for internal threads, especially for completed parts. One of the most common problems with taps is that they leave incomplete threads in blind holes. Moreover, when they fail they tend to get stuck into the piece, causing potential damage and forcing the operator to waste time trying to retrieve the tool that´s now integrated into the piece.

Carbide thread mill NPT tools operate following a different process. First of all, carbide is an extremely hard and rigid composite material. It is virtually impervious to tool deflection, at least if you don’t drive the tool farther than 2.5 times its diameter.

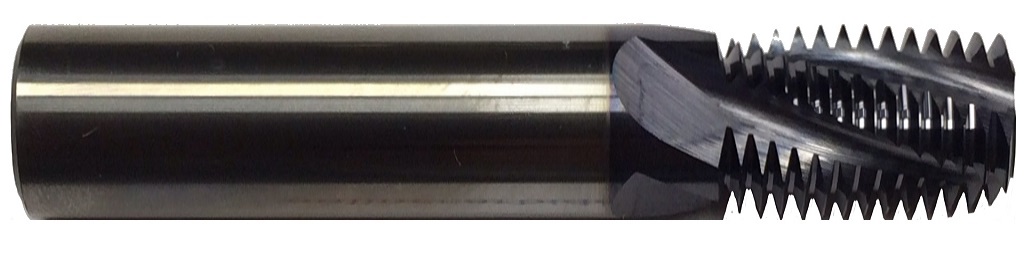

Moreover, full-form carbide NPT thread mills can produce a wide variety of diameters. Tap size is always fixed and determines the diameter they can create, this is the main reason they´re so hard to retrieve when they fail. When thread milling, the diameter is not determined by the tool but by the toolpath created with the CNC. Full form carbide thread mill NPT cutting tools have a row of cutting points or teeth along their length. When they execute a single 360-degree pass, they create a perfectly formed threaded surface. Because of the nature of carbide, the threads created by this tool are of the highest quality, increasing the efficiency of your threading processes.

Thread mills also allow you to create either left or right-handed threads, and also use the same tool for internal and external machining, without the need of changing tools every time you need to perform a different task.

However, you need to make sure you are using the best tools for the job. Online Carbide is an American manufacturer that specializes in providing high-quality carbide tools for high-performance manufacturers nationwide. Visit their website or contact them at [email protected] to find out more about their carbide thread mill NPT tools.