Today, nobody denies the importance of carbon fiber as a super material. This composite has proven to be a high-performance product that yields amazing benefits and incredible versatility. However, it is also a very expensive material, so you always need to make sure your carbon fiber products manufacturer can deliver high-quality sheets and veneers reliably.

But, how do we know we are getting top-quality carbon fiber products?

Here are five factors that can help you determine if you are dealing with the right carbon fiber products manufacturer.

Sheet Flatness

Carbon fiber generally comes in sheets that should lie perfectly flat. Before investing, you must make sure that your sheet does not present any wrinkles, waves, bends, creases, or warps anywhere. If you are not sure if your carbon fiber sheet is high quality, place it on a flat surface and get down to eye level and proceed to inspect.

High Percentage Of Carbon Fiber

This one sounds difficult to detect as it is impossible to determine the percentage of carbon fiber in a sheet with the naked eye. However, there are ways to do this and have an idea of the quality of the carbon fiber sheet. Hold the sheet against a strong source of light and check for pinholes.

Any pinholes or voids indicate a low concentration of carbon fiber. It is good to remember that every 1% of voids in the sheet represents a 10% reduction in performance which is an intolerable margin when producing high-performance carbon fiber products.

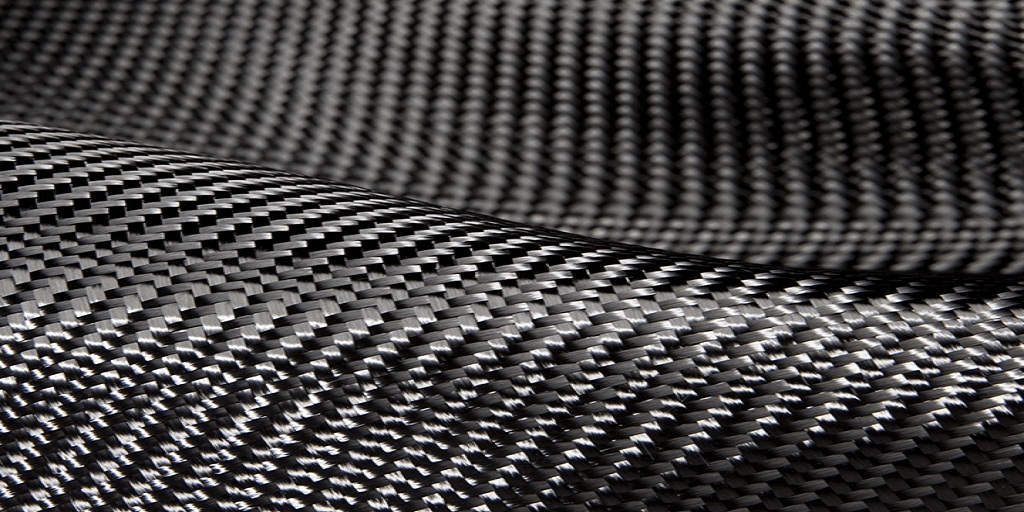

Uniform Fiber Direction

Carbon fiber is extremely sought after due to its mechanical properties. It is incredibly lightweight, rivaling dependable materials such as aluminum, but also has incredible strength and rigidity which can be compared to that of titanium or steel. This weight to strength ratio makes it ideal for engineering projects that require increased performance.

However, carbon fiber sheets are usually anisotropic. It means that the direction in which the fiber flows determines its strength and stiffness. To make the most of this material, the carbon fiber products manufacturer must produce sheets with fibers flowing in a consistent direction.

When inspecting a carbon fiber sheet, confirm that there are no variations in the fiber direction. Any distortion or deviation will cause the final product to have compromised structural integrity and will look terrible too.

No Micro-Fissures

A high-quality carbon fiber sheet will have no micro-fissures on the surface. These are tiny hairline fractures that can cause problems down the line. If undetected, they can lead to a decrease in the product’s overall strength and even delamination.

To check for micro-fissures, you might need a magnifying glass. If you see any fractures on the surface of the sheet, it is a clear sign that the quality of the carbon fiber is not up to par.

Gloss and Matte Carbon Fiber Sheets

Gloss sheets and veneers are mostly used for decorative applications. They must show impeccable luster and effectively look like glass for them to be high quality. Inspect the finishes, looking for small bumps, ridges, or indentations as these could cause problems or delamination. Also, check that the threads beneath the crystal clear epoxy do not look crushed or flattened. Gloss carbon fiber sheets must perfectly display the delicate texture of the fibers.

Matte carbon fiber sheets also have an epoxy finish, but they are not as reflective. However, you must pay equal attention to thread disposition and the quality of the finish to make sure you are getting high-quality carbon fiber sheets.

But Small Defects Are Normal, Right?

Absolutely not. A small defect might be tolerable in other composite materials, but not carbon fiber. Any inconsistency or impurity in the sheet will cause the material to fail. So a good carbon fiber products manufacturer will ensure that their sheets are 99.99% defect-free. Protect Composites is among the most reliable carbon fiber products manufacturers today, and tests all of their sheets to guarantee the highest performance for your project. Visit their website or call them at (360) 573-7800 if you want more information about their incredible products.