Fire has long been a threat to seagoing vessels, and after the introduction of power propulsion and electricity, the risk has only multiplied.

Follow these tips and suggestions to protect your vessel and yourself from the risk of fire and electrical shock while on the water.

Recognize Codes and Standards

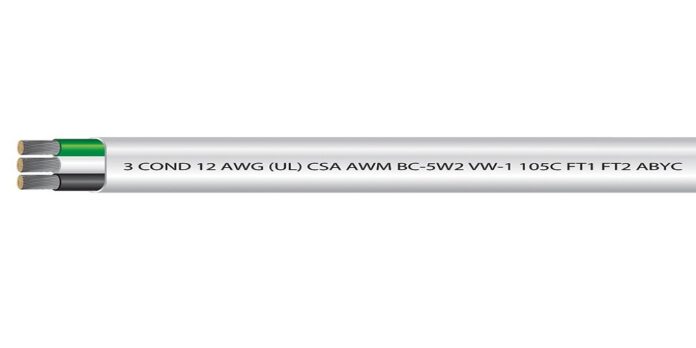

There are several bodies that issue approval for marine electrical cables and equipment. Among these are the National Electrical Code (NEC), Underwriters Laboratory (UL), ABYC (American Boat and Yacht Council), USCG (United States Coast Guard), Electrotechnical Commission (IEC), and National Fire Prevention Association (NFPA).

Recognizing these codes and approvals can help you choose the proper equipment when working on marine electrical systems.

Use Only Approved Marine Battery Cable for Wiring

Never use anything other than an approved marine battery cable or marine-grade electrical cable for wiring on a boat.

Not only is marine-grade electrical wire fine-stranded and much more flexible (and therefore easier to work with) it is made of individually-tinned copper conductors that are better at resisting corrosion.

Marine environments can easily damage wire, causing corrosion that travels along the wire and up, under the insulation. As the wire corrodes, resistance increases and produces more heat that can create a strong fire risk.

Also, all wire you use should be of an appropriate gauge, if not larger, for the job, as using wire that is too thin will cause overheating during use and will increase the risk of fire.

Replace Damaged Marine Battery Cable and Electrical Wiring Immediately

Marine-grade electrical wire’s insulation can be damaged by sunlight, abrasion, salt exposure, and incidental contact with oil, gasoline, grease, and other chemicals.

Always inspect your exposed electrical wiring before a trip on the water and do not proceed if the wiring is frayed, worn, or damaged in any way. Have it assessed and replaced by a qualified electrician before taking the vessel on the water.

Maintain Good Connections; Protect Them

Periodically check your electrical connections, such as at the battery terminals, and ensure they are tight. Loose connections can overheat, produce shorts, and throw sparks, which produce a risk not only of fires but of explosions.

All exposed electrical fittings (such as at terminals) should be protected with an approved, marine-grade dielectric grease which will help insulate them and protect them against corrosion.

Keep Covers Closed

Battery compartments, fuse panels, junction boxes, and other electrical enclosures should be kept closed at all times. This helps keep moisture, salt, and debris out. Never open them unless performance maintenance.

(As another note on working around batteries, be cautious when doing so, as batteries can leak toxic and explosive gases.)

Consider an ELCI

To protect swimmers, consider having an Equipment Leakage Circuit Interrupter installed to prevent electricity from leaking into the water (which can be a danger to swimmers).

Where Can You Get High-Quality Marine Battery Cable?

Looking for high-quality marine battery cable? Look no further than EWCS Wire. They produce a wide range of high-quality electrical cable and wire, not only marine-grade wire but alsospecialized fire alarm and instrumentation cable, armored cable, solar panel cable, submersible pump cable, welding cable and more.