The following terms and designations are fundamental to understanding thread type, form, and more. The following terms and designations are fundamental to understanding thread type, form, and more.

● Class of thread:

An alphanumerical designation indicating a thread’s grade of tolerance or allowance. Common thread classes are categorized under Metric, NPT, UN, and ACME designations.

● Crest:

The portion of the thread which joins the flanks of the thread; the “highest” portion, furthest away from the cylinder.

● Flank:

One of two surfaces connecting the crest with the root at the base of the thread.

● Helix angle:

The angle between a thread’s helix and a line parallel to the axis of rotation.

● Major diameter:

Diameter of the major cylinder, for straight threads. The distance from one thread’s crest to the corresponding thread’s crest on the other side, traveling perpendicular to the axis of rotation.

● Minor diameter:

The diameter of the minor cylinder, for straight threads. The distance from one thread’s root to the corresponding root on the other side, traveling perpendicular to the axis of rotation.

● Pitch:

Distance between corresponding points on threads, taken parallel to the thread axis; for instance, crest to crest, parallel to the thread axis, gives a pitch measurement.

● Root:

The surface of the thread which is adjacent to the cylinder or cone from which the thread rises.

● Thread angle:

The angle between the thread flanks. For instance, NPT threads have a 60° thread angle. Thread Types

There are many standard thread types, among the following:

● ACME:

ACME threads were developed in the late 1800s to replace square threads and feature a trapezoidal thread form, with a “flat” crest. They are strong, easy to manufacture, and often used for lead screws.

● American Pipe Threads (NPT, NPTF):

National Pipe Tapered Threads or National Pipe Tapered for Fuels, both with a 60° thread angle. These require thread sealant for a leakproof seal.

● BSPP:

British Standard Pipe Parallel Thread, with a thread flank angle of 55°.

● BSPT:

British Standard Pipe Taper Thread, also with a thread flank angle of 55°.

● UN:

Unified National Threads, commonly used screw, nut, and bolt threads in the United States and Canada. They have a flank angle of 60°.

Where Can You Get High-Quality Thread Mills for Pipe Threading?

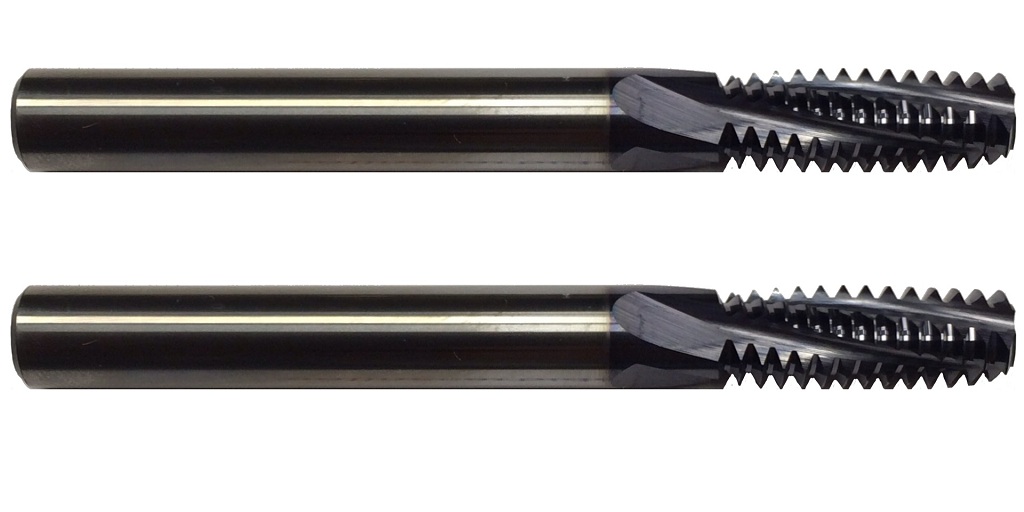

Thread mills for pipe threading represent a significant improvement over cutting threads with a tap and die.

Thread milling is superior for cutting threads on exotic materials, softer non-ferrous alloys, and materials with thin walls. Thread milling uses mills that are more stable, have fewer limitations, and offer superior chip evacuation.

They are also faster and more efficient than taps and dies, and produce higher-quality threads. Moreover, one thread mill for pipe threads has greater flexibility and can cut both internal and external threads, whereas a tap and die can only be used to cut one type in a specific size.

If you’re looking for high-quality thread mills for pipe threading, visit Online Carbide online at OnlineCarbide.com. They carry a wide variety of solid carbide cutting tools and thread mills, including mills for NPT, NPT, UN, and metric threads, and select orders even qualify for free shipping.